Umcu wobhedu okhonkxiweyoyimathiriyeli yentsimbi enomaleko wetoti kumphezulu wobhedu. Inkqubo yokuvelisa i-copper strip enkonkxiweyo yahlulwe yangamanyathelo amathathu: unyango lwangaphambili, ukufakwa kwe-tin kunye nasemva kokunyanga.

Ngokweendlela ezahlukeneyo zokufakwa kwetoti, inokwahlulwa ibe yi-electroplating kunye ne-hot-dip plating. Kukho iiyantlukwano phakathi komcu wobhedu onetoti ene-electroplated kunye nediphu eshushuumcu wobhedu okhonkxiweyokwiinkalo ezininzi.

I. Inkqubo yomgaqo

1) Electroplating tinning: Isebenzisa umgaqo electrolysis ukusebenzisaumcu wobhedunjenge-cathode kunye ne-tin njenge-anode. Kwisisombululo se-electroplating esine-tin ions, i-tin ion iyancitshiswa kwaye ifakwe phezu kwendawo yobhedu yobhedu ukuze yenze i-tin-plated layer ngokusebenzisa isenzo sangoku ngokuthe ngqo.

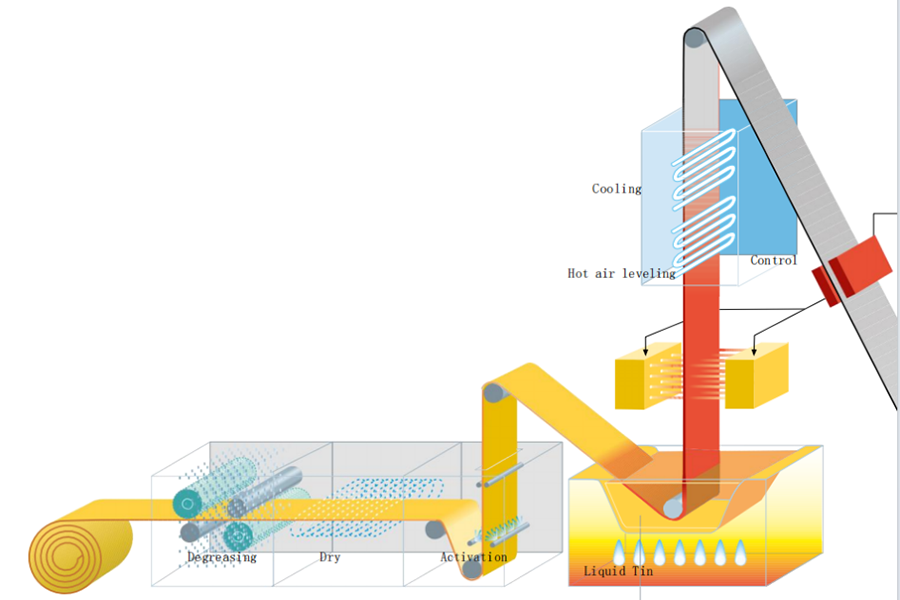

2) Hot-dip tinning: Kukuntywiliselaumcu wobhedukulwelo lwenkcenkce etyhidiweyo. Phantsi kweemeko ezithile zobushushu kunye nexesha, ulwelo lwenkcenkce lusabela ngokwasemzimbeni nangokwekhemikhali ngomphezulu wecwecwe lobhedu ukwenza umaleko wenkcenkce kumphezulu wesicu sobhedu.

II. Iimpawu zokugquma:

1) Ukwaleka ukufana

A) I-Electroplating tinning: Ukufana kokugquma kulungile, kwaye kunokwenza umaleko ofanayo kunye nobuthathaka obuthambileyo bokwetha phezu komhlaba.umcu wobhedu. Ngokukodwa kwimicu yobhedu enemilo enzima kunye neendawo ezingalinganiyo, inokuphinda igubungele kakuhle, efanelekile kwiimeko zesicelo kunye neemfuno eziphezulu zokugqoka okufanayo.

B) I-Hot-dip tinning: Ukulingana kokugquma kumbi kakhulu, kwaye ukutyeba okungalinganiyo kokwambathisa kunokwenzeka kwiikona nakwimiphethoumcu wobhedu. Nangona kunjalo, kwezinye iimeko apho iimfuno zokufana kwengubo zingekho ngqongqo ngakumbi, impembelelo incinci.

2) Ubukhulu bokugquma:

A) I-Electroplating tinning: Ubukhulu bokugquma buthe tye, phakathi kwe-microns ezimbalwa kunye namashumi eemicrons, kwaye inokulawulwa ngokuchanekileyo ngokweemfuno ezithile.

B) I-Hot-dip tinning: Ubukhulu bokugquma budla ngokuba ngqindilili, ngokubanzi phakathi kwamashumi eemicrons kunye namakhulu eemicrons, ezinokubonelela ngokuxhathisa ukudleka okungcono kunye nokumelana nokunxiba.imicu yobhedu, kodwa isenokungalungeli ezinye izicelo ezinezithintelo ezingqongqo kubunzima.

III. Ukusebenza kakuhle kwemveliso

I-1) I-Electroplating tin plating: Inkqubo yokuvelisa inzima kakhulu, ifuna iinkqubo ezininzi ezifana nonyango lwangaphambili, i-electroplating, kunye ne-post-treatment. Isantya semveliso sincinci kwaye asifanelekanga kwimveliso emikhulu kunye nephezulu. Nangona kunjalo, kwezinye iibhetshi ezincinci kunye neemfuno zemveliso ezilungiselelweyo, i-electroplating tin plating inokuguquguquka okuhle.

2) I-Hot-dip tin plating: Inkqubo yokuvelisa ilula. Inkqubo yokufakwa kwe-tin ingagqitywa ngokuntywiliselwaumcu wobhedukulwelo lwetoti. Isantya semveliso sikhawuleza kwaye sinokuhlangabezana neemfuno zemveliso enkulu.

IV. Amandla okudibanisa:

I-1) I-Electroplating tin plating: Amandla okudibanisa phakathi kwengubo kunye neumcu wobheduisubstrate yomelele. Oku kungenxa yokuba ii-ion ze-tin zenza ii-chemical bonds kunye nee-athom ezikumphezulu we-copper strip phantsi kwesenzo sommandla wombane ngexesha lenkqubo ye-electroplating, okwenza ukuba kube nzima ukuwa phantsi5.

2) I-Hot-dip tin yokucwenga: Amandla okudibanisa nawo alungile, kodwa kwezinye iimeko, ngenxa yokusabela okuntsokothileyo phakathi kolwelo lwetin kunye nomphezulu we-tin.umcu wobhedungexesha lenkqubo yokucoca i-hot-dip, ezinye iipores ezincinci okanye iziphene zingavela, ezichaphazela amandla okudibanisa. Nangona kunjalo, emva konyango olufanelekileyo lwasemva konyango, amandla okubopha i-hot-dip tin plating nawo angahlangabezana neemfuno zezicelo ezininzi.

V. Ukuchasa ukuMdla:

I-1) I-Electroplating tinning: Ngenxa yokugquma okucekeceke, ukuxhathisa kwayo kokubola kubuthathaka. Nangona kunjalo, ukuba inkqubo ye-electroplating ilawulwa ngokufanelekileyo kwaye ifanelekileyo emva konyango, njenge-passivation, iqhutywe, ukuxhathisa ukubola kweumcu wobhedu okhonkxiweyoinokuphuculwa

2) I-Hot-dip tinning: I-coating ingqindilili, enokubonelela ngokhuseleko olungcono lokumelana ne-corrosionumcu wobhedu. Kwiimeko ezirhabaxa zokusingqongileyo, ezinjengendawo efumileyo kunye nerhasi eyonakalisayo, inzuzo yokuchasa ukugqwala kwediphu eshushu.umcu wobhedu okhonkxiweyoicace ngakumbi5.

VI. Iindleko

I-1) I-Electroplating tinning: Utyalo-mali lwezixhobo luncinci, kodwa ngenxa yenkqubo yemveliso entsonkothileyo, isebenzisa umbane ongaphezulu kunye nee-reagents zeekhemikhali, kwaye ineemfuno eziphezulu zommandla wemveliso kunye nabaqhubi, ngoko ixabiso lemveliso liphezulu kakhulu.

2) I-Hot-dip tinning: Utyalo-mali lwezixhobo likhulu, kwaye kufuneka kwakhiwe iziko lobushushu obuphezulu kunye nezinye izixhobo, kodwa inkqubo yokuvelisa ilula kwaye ukusetyenziswa kwezinto ezikrwada kuncinci, ngoko ke ixabiso leyunithi linokuba lincinci kwimveliso enkulu.

Ukukhetha aumcu wobhedu okhonkxiweyoifanelekile kwimeko yesicelo sakho idinga ukuqwalaselwa ngokubanzi kwezinto ezininzi ezifana neempawu zombane, iimpawu zomatshini, ukuxhathisa ukubola, inkqubo yokuvelisa, iindleko kunye nokukhuselwa kokusingqongileyo. Ngokweemfuno ezithile, linganisela okuhle kunye nokubi kuzo zonke iinkalo kwaye ukhethe eyona ifanelekileyoumcu wobhedu okhonkxiweyoukuqinisekisa ukusebenza kunye nomgangatho wemveliso.

Ixesha lokuposa: Sep-18-2024