I-nickel yobhedu yi-alloy ye-copper-base kunye ne-nickel njengeyona nto idibanisayo.Izibini ezidumileyo kwii-alloys ezinobhedu ziqulethe i-10 okanye i-30% ye-nickel.Ngokudibanisa i-manganese, isinyithi, i-zinc, i-aluminium kunye nezinye izinto, iba yinto eyinkimbinkimbi ye-nickel alloy ngeenjongo ezikhethekileyo.

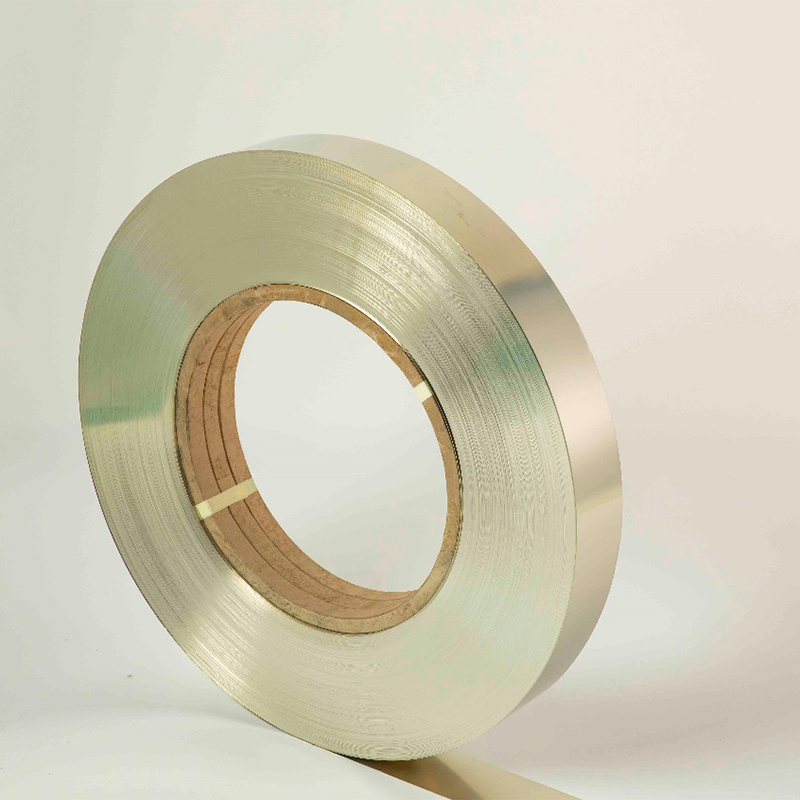

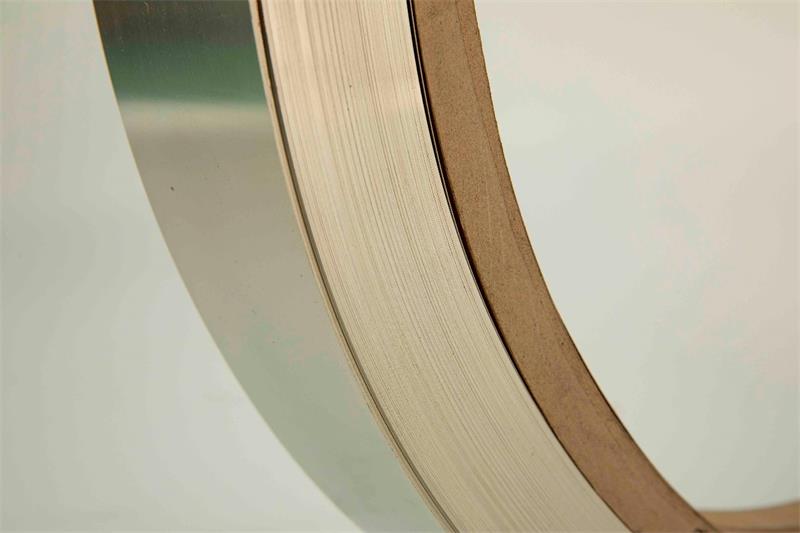

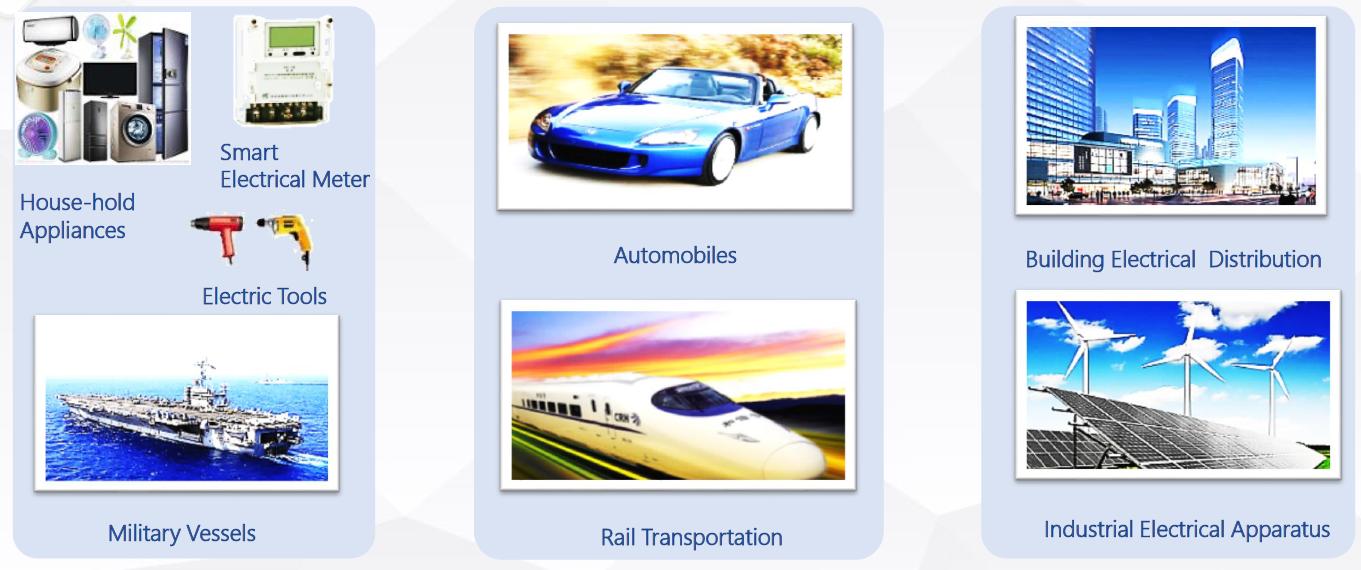

I-Nickel ye-Zinc Copper inezixhobo ezigqwesileyo ezibanzi zoomatshini, ukumelana nokugqwesa okugqwesileyo, ukubanda okulungileyo kunye nokubumba okutshisayo, ukusika okulula, kunokwenziwa ngocingo, ibha kunye nepleyiti, esetyenziselwa izixhobo zokuvelisa, iimitha, izixhobo zonyango, iimfuno zemihla ngemihla kunye nonxibelelwano kunye nezinye iinkalo. yamalungu achanekileyo.